|

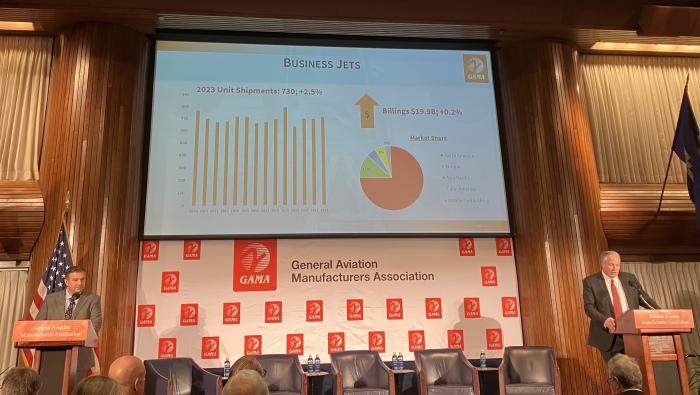

Aircraft deliveries were up across all sectors in 2023, according to the year-end statistics released today by the General Aviation Manufacturers Association (GAMA). Airplane billings rose by $500 million last year, while rotorcraft billings climbed by $400 million. “For the first time in over a decade, the general aviation manufacturing industry has eclipsed 4,000 aircraft delivered,” noted GAMA president and CEO Pete Bunce, speaking this afternoon at the organization's State of the Industry press conference in Washington D.C. “In addition to this strong showing, there are robust and growing order backlogs for all segments of aircraft.” For the business jet category, last year saw a total of 730 deliveries, a 2.5 percent increase from 2022, while the turboprop segment overall experienced a 9.6 percent increase from 2022. Among high-end pressurized turboprops, the improvement was 7 percent, and piston-powered aircraft saw a nearly 12 percent increase in 2023, with 1,682 aircraft handed over. Deliveries in the rotorcraft segment rose by nearly 10 percent last year compared to 2022. The turbine-powered category showed even better performance with its 753 deliveries equating to a 10.4 percent boost. “While the deliveries from 2023 are very encouraging, our industry faces headwinds from ongoing supply chain issues, workforce shortages, uncertainty and unpredictability from global regulators, and short-sighted efforts aimed at curbing business and general aviation, particularly in Europe,” said Bunce. |

|

|

Brisbane, Australia-based Heston MRO has acquired fellow Australian maintenance support provider Aviation NDT Services. Calling itself the largest independent “total care” MRO in Australasia, Heston says its acquisition of Melbourne-based Aviation NDT will further expand its offerings within the general and commercial aviation markets. Established in 1986, Aviation NDT Services performs non-destructive testing and inspection on a range of general aviation and airline customers in Australia, the Pacific Island region, and Asia. “We are very excited about Aviation NDT Services joining the Heston MRO family,” said Heston MRO chief executive Asta Zirlyte. “We aim to have a seamless integration of the two businesses as one Heston MRO NDT Unit by continuing to provide NDT services to existing general aviation customers and expanding our range into [the] wider commercial aviation marketplace. We see solid growth potential to provide services to the larger national and international airlines and defense customers in the region.” Heston MRO’s NDT Unit expects to obtain CASA Part 145 approval for Rating D services to establish a training ground for NDT career development for its current and new employees. |

|

|

ExecuJet Haite Aviation Services China has signed an agreement with Capital Airport Holding Business Management (CBM) to provide line maintenance and AOG services at Beijing Capital International Airport. The collaboration in Beijing expands upon the agreement ExecuJet reached with CBM in December for MRO services at Beijing Daxing International Airport. CBM offers FBO services at both of Beijing's international airports. “We continue to look for ways to create more value for our entire business jet operation,” said Li Yiyong, general manager of CBM. “This agreement will allow us to work cooperatively with ExecuJet Haite in providing outstanding maintenance support and services to our shared clientele as we operate at one of the busiest business aviation destinations in the region.” ExecuJet Haite, which operates its MRO in Tianjin, will offer support for a range of aircraft types at the expanded locations under its authorizations from the Civil Aviation Administration of China and other national authorities. Paul Desgrosseilliers, ExecuJet Haite's general manager, said the expansion of its maintenance services “demonstrates our unwavering commitment towards supporting our customers in China and wider Asian region.” |

|

|

MRO provider Elliott Aviation is launching the Citation XL/XLS Excellence Program, a complete maintenance, interior, paint, and avionics upgrade of the popular twinjet. Components include scheduled maintenance, upgraded interior with options, new paint, and installation of the Garmin G5000 digital avionics suite. The program also features guaranteed downtime and preferred labor rates on maintenance. Elliott has been installing the G5000 upgrade in the Excel/XLS since it was certified in 2019. Between 1998 and 2004, Cessna delivered 370 Excels and, at its peak, produced more than 100 per year. A follow-on model, the XLS, sold 329 copies between 2004 and 2009. The main difference between the Excel and the XLS is that the latter provides updated avionics, a 200-pound gross weight increase, and more engine thrust via the uprated PW545B engines, thus eliminating the need to step climb to the aircraft’s 45,000-foot maximum cruising altitude. Fractional ownership company NetJets at one time operated more than 100 of them, and membership jet service Wheels Up uses the model as the mainstay of its jet fleet. According to aircraft valuation service Vref, used Excels are trading in the $3 million to $4.3 million range, while used XLSs are fetching between $5 million and $6.6 million. More than 120 XL/XLSs had been converted to the G5000 avionics as of late 2023. |

|

|

The FAA recently approved a new airframe and powerplant (A&P) mechanic program at the Universal Technical Institute (UTI) Miramar, Florida campus. Classes are underway now for the 18-month course of study. UTI said the new program will teach students to diagnose, repair, and maintain aircraft, powerplants, and their components. This is the educational institute's fifth A&P program, and it joins UTI facilities with A&P programs in Avondale, Arizona; Long Beach, California; Canton, Michigan; and Houston. “We continue to optimize our existing campus footprint to offer more workforce solutions in regions where they are most in demand," said Universal Technical Institute president Tracy Lorenz. "The new aviation program at the Miramar campus is an excellent example of how we work with local leaders to help support a well-trained workforce and further their economic goals." Lorenz added that the A&P course is one of 14 new programs offered by the institute, with the goal of providing education in skilled trades and energy fields. Total aviation technician employment is expected to exceed 146,000 by 2032, according to the Bureau of Labor Statistics. "Demand for aviation technicians is being driven, in part, by a rebound in post-pandemic air travel, as well as a wave of retirements among industry workers," according to UTI. |

|

|

ExecuJet MRO Services Australia’s facility in Perth has become an authorized service center for Embraer’s business jets. Under an agreement announced on Tuesday, the company will provide support for the Brazilian airframer’s customers in Australia and other parts of the Asia-Pacific region. Initially, support will be available for operators of Embraer’s Legacy 600 and 650 aircraft. ExecuJet said it has invested in new tools and training for the service offering. “With proximity to Southeast Asia, it made sense to make Perth one of our centers of excellence for Embraer aircraft,” said Grant Ingall, ExecuJet MRO Services’ vice president for Australasia. ExecuJet MRO Services, which is wholly owned by Dassault Aviation, has operated Embraer-authorized service centers at its Melbourne and Sydney locations since 2010. This means it can manage Executive Care support and warranty claims for spare parts and labor for the manufacturer. The company also provides support for a variety of business aircraft made by Dassault, Bombardier, Gulfstream, and Textron Aviation. In addition to maintenance approval from the Australian Civil Aviation Authority, it has clearance to do heavy maintenance checks on Embraer aircraft from the FAA and the air safety agencies in Bermuda, Cayman Islands, San Marino, Vietnam, and Indonesia. |

|

|

Helicopter Association International (HAI) will promote the use of sustainable aviation fuel (SAF) next week during the annual Heli-Expo showcase in California. Show organizers are expecting 60 aircraft to arrive starting on February 26, including 45 that will be flown to the Anaheim Convention Center from a staging area at Fullerton Municipal Airport. At Fullerton, HAI will have SAF on hand for use by turbine-powered helicopters. SAF is produced from organic materials, such as oils, algae, fats, alcohols, sugars, and captured carbon dioxide. In its neat, unblended form, it can reduce lifecycle greenhouse gas emissions by as much as 80 percent compared to traditional petroleum-based jet fuel. This is important for the aviation industry, which according to the EPA contributes up to 12 percent of the U.S. transportation sector’s emissions. SAF presently makes up a minute portion of the overall fuel supply and comes at a higher cost than conventional jet fuel, two factors HAI president and CEO James Viola said need to be overcome. “HAI is doing what we can to bring down the cost of SAF and increase its use,” he said, adding that the organization recognizes the importance of reducing the industry’s impact on the environment. “Some aviation customers or clients will prefer using operators who utilize SAF as it upholds their corporate values or permits them to report a reduced environmental impact.” |

|

|

|

|

|

|

AINalerts News Tips/Feedback: News tips may be sent anonymously, but feedback must include name and contact info (we will withhold name on request). We reserve the right to edit correspondence for length, clarity, and grammar. Send feedback or news tips to AINalerts editor Chad Trautvetter. |

|

AINalerts is a publication of AIN Media Group, 214 Franklin Avenue, Midland Park, New Jersey. Copyright 2023. All rights reserved. Reproduction in whole or in part without permission is strictly prohibited. |