|

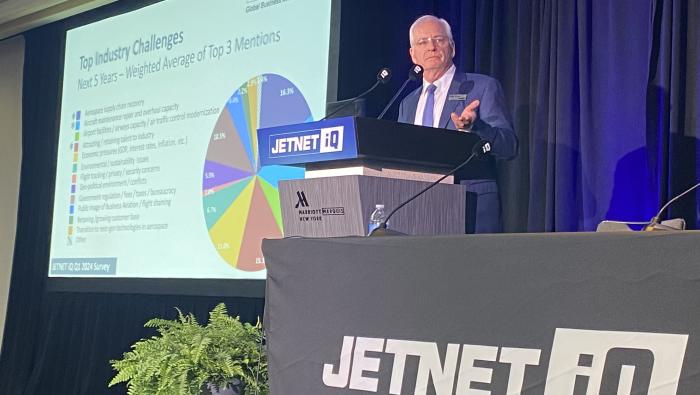

JetNet’s latest quarterly survey shows growing uncertainty and pessimism in the business aviation industry. Speaking this afternoon at the company’s annual iQ Summit, Rolland Vincent, iQ survey founder and the head of Rolland Vincent Associates, noted that in the company’s third-quarter survey, almost 60% of the 400 respondents indicated that they felt the industry had not yet reached the low point in the current business cycle, outnumbering those who believe the economy was on an upswing nearly 2-to-1. In the U.S.—the world’s largest business aviation market—industry net optimism has reached its lowest point since the initial Covid surge in 2020, with little variance among the aircraft operator segments. “We’re in a bit of a strange place,” said Vincent. “Part of it is geopolitical tensions, presidential election uncertainties for sure, changes in interest rates, inflation, all these sorts of things, and just general tensions around wealth.” Yet despite this short-term pessimism, half of the survey respondents indicated they expected to increase the utilization of their aircraft over the next five to 10 years, while 46% anticipated enlarging their current business aircraft fleet. Vincent noted continued stabilization in the preowned jet market as some young aircraft have begun to appear on the market for the first time in several years. “The market is moving and it’s normalizing back up to 7% to 8% of the fleet,” he told attendees. |

|

|

A third major business jet OEM—Textron Aviation—has opted against participating in NBAA-BACE, the association’s flagship event, next month in Las Vegas. Textron Aviation this morning released a statement saying it “continues its focus on designing and delivering the best aviation experience for our customers as we maintain our business operations during this time. With that, Textron Aviation and TRU Simulation, a Textron Aviation affiliated company, will not participate as exhibitors at the 2024 NBAA-BACE.” The company added that it appreciates its longstanding involvement in industry events and looks “forward to future opportunities to showcase our industry-leading products.” While not elaborating further, the decision comes amidst a strike at Textron Aviation that began on Monday involving 5,000 members of the International Association of Machinists Local Lodge 774 District 70. The strike came despite the local bargaining committee’s recommendation that members accept the company’s offer. But its decision to pull out just weeks ahead of this year’s NBAA-BACE, which will be held from October 22 to 24, comes as a surprise. In fact, Textron Aviation hosted a media briefing in advance of NBAA-BACE two weeks ago. For NBAA, however, the decision follows those of Gulfstream and Dassault to bypass this year’s BACE. Gulfstream has emphasized that it is looking at smaller, more regional events to reach its customers, while Dassault is believed to be opting for an every-other-year mode. |

|

|

In a letter of interpretation issued earlier this month, the FAA clarified that the term “in person” in Part 43 maintenance regulations means that remote supervision of aircraft maintenance is forbidden. This could have a profound effect on the aviation maintenance industry because the letter essentially supports a requirement that a supervising mechanic must watch every move made by a non-licensed individual performing maintenance. The request for interpretation was submitted by Jonathan Moss, manager of the FAA’s Flight Standards District Office in Little Rock, Arkansas. Moss asked “whether a supervisor must be physically present at the site of the maintenance, or if he may supervise remotely, through Zoom, FaceTime, live feed TV, photographs, downloadable video, or other electronic means.” Per FAR 43.3(d): “A person working under the supervision of a holder of a mechanic or repairman certificate may perform the maintenance, preventive maintenance, and alterations that his supervisor is authorized to perform, if the supervisor personally observes the work being done to the extent necessary to ensure that it is being done properly and if the supervisor is readily available, in person, for consultation.” According to the FAA letter, “The Office of the Chief Counsel finds that the phrase ‘in person’ explicitly requires physical presence. Virtual presence, through a live video feed or other technological means, cannot replace the physical presence of a supervising mechanic.” |

|

|

The first day of the JetNet iQ Summit was punctuated by both cautious optimism for sustainable aviation fuel (SAF) solutions and marked criticism of those in the political arena who have criticized the business aviation industry for its perceived role in climate change. In a panel titled “Net Zero: Altitude, True Airspeed, Fuel Reserves, and Distance to Destination,” panelist Mahlet Garedew talked about her company’s efforts to turn CO2 into a usable fuel source. Garedew is the innovation program manager at Air Company. “Our process is CO2 agnostic. You can get your CO2 from a power plant or you can get it from a biogenic source; you can get it from direct air capture,” she said. “That’s kind of our model, being able to deploy technology anywhere, even in New York City.” In the following panel titled “Business Aviation and Climate Change: Today, Tomorrow”, Holger Krahmer—secretary-general of the European Business Aviation Association (EBAA)—did not hold back in his criticism of the European Commission’s previous attitudes towards business aviation. “The last European Commission was, in my point of view, with my 20 years of Brussels experience, the most business-unfriendly European Commission we ever had,” he said. |

|

|

Sponsor Content: PremierMRO The art of the pre-buy inspection: An expert pre-buy spares new owners many headaches, and potentially high post-sale costs. Sales go more smoothly, with discrepancies resolved to buyer and seller satisfaction. PremierMRO has been conducting win-win pre-buys for decades. It’s a full-service center with expertise on most popular models. |

|

|

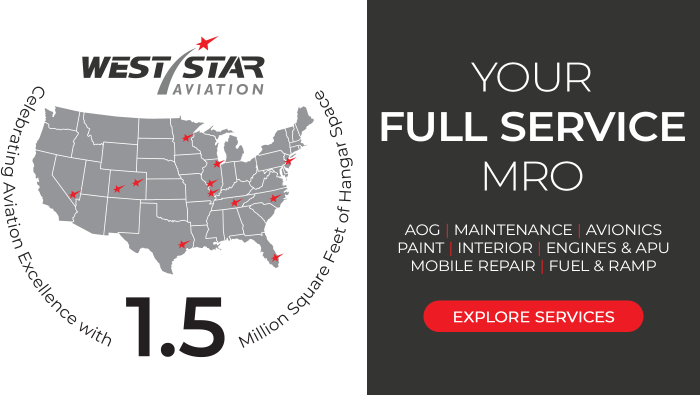

Duncan Aviation is kicking off construction in December on a $25 million paint facility at its Lincoln, Nebraska location. Plans call for a 32,500-sq-ft dual-bay hangar with an additional 9,000-sq-ft storage and support area that will connect to the MRO provider’s existing paint facility built in 2012. The project also entails expansion of the ramp on the building’s west side. Designed and engineered by long-time Duncan Aviation partner Tectonic Management Group, the facility will feature cross-draft bays with updated climate control, as well as upgraded wastewater treatment and added air showers to contain more contaminants. It will further have a small application booth for parts such as flaps and thrust reversers. Other features include dimmable hangar lighting that provides flexibility for future layouts and the ability to recirculate up to 80% of the heat of the curing processes. Construction is anticipated to be complete by January 2026. Once open, Duncan plans to decommission its Paint Bays 1 and 2, which were built in 1990; that area will be repurposed. However, the 45,000-sq-ft paint facility built a little more than a decade ago will remain in use. The new facility will accommodate large models such as the Gulfstream G650, Dassault Falcon 10X, and Bombardier Global 7500, as well as provide flexibility for unscheduled and drop-in work such as paint touch-up and registration number changes. |

|

|

Broomfield, Colorado-based Blackhawk Performance Center (BPC) this week received FAA Part 145 repair station certification. This approval allows the Blackhawk Group facility to provide comprehensive maintenance services for Beechcraft King Airs, as well as avionics sales, installation, and support for King Airs and Cessna Citations. “Receiving the FAA Part 145 certification is a testament to our unwavering commitment to safety, quality, and excellence in the aerospace industry,” said BPC sales director Beau Hawkins. “With this certification in hand, we stand ready and excited to support the broad needs of turboprop and light jet aircraft owners and operators.” Besides offering full-service MRO capabilities for King Airs, the Broomfield shop can now install Blackhawk’s XP Engine+ upgrades on the turboprop twins. The facility can also perform Pratt & Whitney Canada PT6 overhauls, repairs, and hot sections. On the avionics side, it is an authorized dealer for Garmin, Collins, Gogo, and AirText. The Blackhawk Group has another BPC in Columbia, Missouri, that also specializes in light turbine aircraft maintenance. Sister company Avex has MRO facilities specializing in Daher TBM turboprops in Broomfield and in Camarillo, California. |

|

|

Vertical Aviation International issued a list of recommendations this morning for the FAA’s anticipated notice of proposed rulemaking (NPRM) on beyond visual line of sight (BVLOS) operations of uncrewed aircraft systems—also known as FAR Part 108. By congressional mandate contained in the 2024 FAA Reauthorization Act, the FAA must publish this NPRM by year-end. This NPRM is expected to closely follow recommendations issued in 2022 by the FAA’s BVLOS advisory and rulemaking committee covering key areas, including see-and-avoid technology, vehicle operation and performance standards and limitations, integration of uncrewed aircraft systems (UAS) into the National Airspace System, and certification and training requirements. “The aviation community must work together to solve the challenges around BVLOS operations and build a future that allows us all to operate safely,” said VAI president and CEO James Viola. Noting helicopters’ unique capabilities and missions, VAI’s recommendations include maintaining existing right-of-way rules in FAR 91.113 with a bias toward vehicle maneuverability or restrictions to maneuver over sense/detect/see capabilities; establishing performance-based standards for BVLOS see-and-avoid requirements; maximum visual or electronic “conspicuity” for all aircraft; rejection of shielded areas and shielded operations for UAS near critical infrastructure and obstacles; and creation of shielded operations where UAS are physically separated from other aircraft such as under bridges and within cooling towers. The comment period for the BVLOS NPRM is expected to run from 30 to 90 days. |

|

|

AOPA yesterday named Darren Pleasance as its new president and CEO, effective Jan. 1, 2025. Pleasance, an experienced pilot with more than 8,000 hours TT in more than 50 aircraft types, brings a background in both aviation and business leadership to the role. His appointment follows the retirement of Mark Baker, who served as AOPA’s president for more than 11 years and played an important role in advocating for general aviation. Pleasance’s aviation experience includes flying for corporate clients, conducting charters in remote areas, and maintaining his status as a certified flight instructor. He operates several aircraft, including a Piper Meridian and a SeaRey floatplane. In addition to his aviation credentials, Pleasance’s career has spanned leadership roles at companies such as Cisco, Google, and McKinsey & Co. Commenting on his new role, Pleasance said, “I'm honored with the opportunity I'm being given to help steward AOPA forward into the future, and I'm inspired by the role AOPA will continue to play in protecting our freedom to fly.” Bill Trimble, chairman of AOPA’s board of trustees, remarked, “After completing an extensive national search, we met with many terrific candidates, but all agreed that Darren brings a wealth of experience coupled with a joy of flying that will be critical for leading AOPA's mission going forward.” |

|

|

|

|

|

|

AINalerts News Tips/Feedback: News tips may be sent anonymously, but feedback must include name and contact info (we will withhold name on request). We reserve the right to edit correspondence for length, clarity, and grammar. Send feedback or news tips to AINalerts editor Chad Trautvetter. |

|

AINalerts is a publication of AIN Media Group, 214 Franklin Avenue, Midland Park, New Jersey. Copyright 2024. All rights reserved. Reproduction in whole or in part without permission is strictly prohibited. |

x790(h)_Sterling%20card_August%202024_EN%5B31%5D.gif)